Today’s contractors are challenged by new infrastructure that need technological advancements that solve real problems with easy to use reliable construction solutions and are conducive for safe and efficient work productivity. Some of those types of advancements may include automated equipment, life cycle optimizing equipment, and digital technologies. These kind of facility advancements are making way for greater originality and value for industrial businesses to meet marketplace demands of the future. The need for industrial construction is still maturing with over $148 billion planned to be spent in the US for various facilities during September 2020 to August 2021 according to Industrial Information Resources.

Whether construction is needed for new heavy manufacturing space, warehousing and distribution, data centers, processing facilities, utility/water infrastructure, equipment addition or expansion, or even a military installation, each project’s future can be better than before with the right construction experts like Bodell Construction.

Here are some of the trends we have seen lead industrial construction into the future.

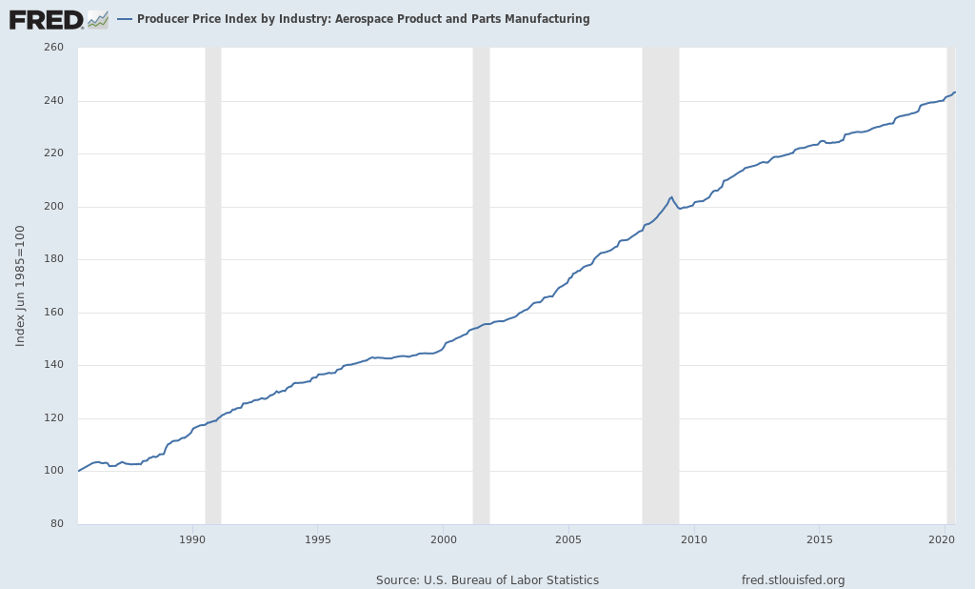

Currently, the need for facilities to deliver ecommerce consumables continues to increase. Companies like Amazon and UPS are expanding their facilities across the US to meet distribution demand including a need to fabricate more shipping boxes. In addition, Military aerospace product and parts manufacturing show real growth according to the Bureau of Labor statistics.

Covid 19 also caused the decrease of airport transportation thereby impacting commercial airfield facilities. Different results occurred for military airfield facilities still needed for Department of Defense (DOD) like Airforce, Navy, and Army National Guard. Procurement activity for DOD construction and design projects typically peak during the summer months to allocate Federal budgeted spending and stimulate the economy for the fiscal year.

A majority of government spending is dedicated annually for architecture, engineering, and construction to support DOD readiness and resilience thus, adding many auxiliary buildings to existing military airfields. Those types of projects we saw trending in 2020 were fueling/tank facility replacements, hangars, munitions buildings, and other vertical construction deemed mission-critical.

Earlier in 2020, Federal funding became more available for many water infrastructure improvements and transportation projects, which caused a spike of this type of construction because of aging, worn-out infrastructure. While these types of projects are typically funded by State and County budgets, those that were boosted with Federal funding went to areas surging with major population growth. Many of these projects are still in various stages of development, design/engineering, or construction.

The government has also created a discretionary budget for meeting goals for energy consumption. This includes construction of combined heat/power plant facilities and biomass facilities. Power plants are also needed for Data Centers. Industrial Information Resources CEO David Pickering, Vice President of Research says, “Data centers are still in demand as they have pushed to the forefront for the last 7 years.” This is because globally, our lives are dependent on electronics and the internet now more than ever with the increased work from home scenarios.

Bodell Construction has learned from its 50 years in business that 4 key factors make these facility types to be built successfully. Number one is Health and Safety. Our goal for zero incidents on every job site is recognized by receiving awards for performance and our commitment to provide a safe work environment. Secondly, robust field operation coordination increases teamwork and communication while embracing modern platforms for meeting, all while promoting internal culture with continuous training and guiding leadership. Third, materials – whether premanufactured or alternative choices, the best options are always analyzed with proactive vendor relationship management, strong cost estimating, and equipment procurement solutions. Fourth, rigorous project monitoring controls of time and cost to manage resources and spearhead transformation. Bodell typically self performs critical scopes including complex mechanical construction, resulting in great efficiency and less risk to schedule growth. Staging and phasing are carefully procured and coordinated so different crews and subcontractors aren’t working on top of each other. This combination not only improves productivity but also reduces project delays yet enhances the quality of building for the success of the facility and its owners.

We believe there is always a better way to serve clients and colleagues, and it begins by being the exceptional, solutions-driven option – the better way. Whether a new building is needed, or an existing building needs repurposing, our aim is to continuously discover, develop, and deliver value-creating solutions that meet a client’s unique needs. If you are looking for a general contractor, contact our Salt Lake City corporate office. We’d love to help.